Die casting ebu

Nkọwa nkenke:

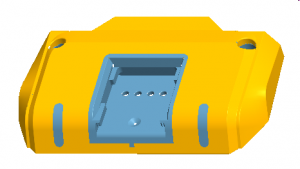

Die mgbatị ebubụ ụdị ngwá maka metal anwụ mgbatị. A na-anwụ casting ebu mejupụtara ebu “cover die ọkara” na ndị ọzọ na “ejector anwụ ọkara.

Die-casting Ebu na-bụ-eji maka akpụ na-abụghị ferrous metal akụkụ na mgbagwoju Ọdịdị na udi. Dika imeputa igwe nke alloy alloy, zinc alloy, alloy magnesium na alloy alloy alloy, nke a na-akacha eji ya na ugbo ala, igwe eletriki, ngwa eletriki, oche, ogwu na ihe ndi ozo.

Gịnị bụ anwụ mgbatị ebu

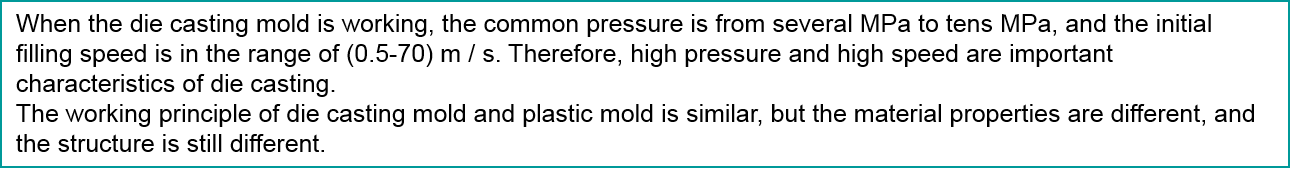

Die mgbatị bụ obere aha mgbali mgbatị. Ọ bụ a usoro jupụta uji eze nke na-anwụ ningfe ebu na mmiri mmiri ma ọ bụ ọkara mmiri mmiri metal n'okpuru elu nsogbu

na nnukwu ọsọ na sie ike iji nweta nkedo. A na-akpọ ebu ahụ eji akpụ akpụ anwụ.

Ofdị nke na-akpụzi ebu

Dị ka ojiji, ọ nwere ike kewaa n'ime bughi akụkụ na ji achọ akụkụ.

Dị ka ngwa ọnọdụ, ọ nwere ike kere n'ime ụgbọala anwụ n automfe ebu, 3C ngwaahịa anwụ n diefe ebu, toy anwụ n toyfe ebu, wdg

Dị ka e ji mara nke udi na mgbidi ọkpụrụkpụ, ọ nwekwara ike-ekewa n'ime mkpa-walled anwụ-mgbatị ebu, igbe anwụ anwụ-mgbatị ebu na diski anwụ-mgbatị ebu

Die mgbatị igwe, anwụ-n allofe alloy na-anwụ-mgbatị anwụ bụ ihe atọ nke anwụ-mgbatị mmepụta, otu onye nke dị oké mkpa.

The ụdị nke na-anwụ-mgbatị igwe, anwụ bughi bughi usoro, anwụ-mgbatị usoro na factory layout na-adabere na-anwụ-n diefe alloy ihe, ya mere na nhazi ọkwa nke na-anwụ-mgbatị anwụ dị ka alloy ihe bụ ihe kasị mma maka mmepụta omume. ha na-anwụ-mgbatị ebu nwere ike kere n'ime aluminum alloy anwụ-mgbatị ebu, zinc alloy anwụ-mgbatị ebu, magnesium alloy anwụ-mgbatị ebu na ọla kọpa alloy anwụ-mgbatị ebu. Nkọwa bụ:

1) .Aluminium anwụ casting ebu

2) .Zinc anwụ ningfe ebu

3) .Magnesium alloy anwụ-ningfe ebu

4) .Copper alloy anwụ-ningfe ebu

5) .Sintering-ebu

Aluminom anwụ n castfe ebu

Zinc anwụ nkedo ebu

Die mgbatị ebu mejupụtara

The mejupụtara nke na-anwụ mgbatị ebu nwere ike Olee ihe enyemaka kewara abụọ n'akụkụ:

Anyịnya ebu ọkara:Ka a ndozi na ofu ebu arịọnụ efere nke na-anwụ mgbatị igwe, na a sprue jikọọ na a onu ma ọ bụ a nsogbu ụlọ;

Ibughari ebu ọkara:Iji dozie ya na efere efere nke igwe na-anwụ anwụ, ma kpalie ya na efere ntinye iji mepee ma mechie ebu ahụ. Mgbe emechiri ebu ahụ, a na-emepụta oghere ebu na usoro nkedo, na mmiri mmiri na-ejupụta oghere ebu ahụ n'okpuru nrụgide dị elu. Mgbe imeghe ebu, ibughari ebu ọkara na anyịnya ebu kwụsị na-iche, na ningfe na-kewapụrụ site na enyemaka nke ejection usoro setịpụrụ na ibugharị ebu ọkara.

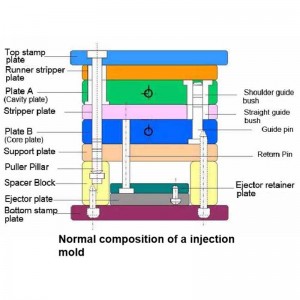

Ọdịdị ọnwụ na-anwụ anwụ na-agụnye sistemụ ndị a dị ka ọrụ ya si dị:

1) Oghere: elu sprue (sprue sleeve); Isi: ọnụ ụzọ dị n'ime nke elu ime.

2) Guide akụkụ: ndu post; ndu ndu.

3) Mwepụta usoro Push rod (thimble), nkwụnye nrụpụta, ihe ntanye na-edozi efere, efere ntinye, ntinye efere nduzi, ntinye efere ntuziaka.

4) Side isi Anam Udeme usoro onyeisi, oghere (n'akụkụ), nkpirikpi ngọngọ, ịgba mmiri, ịghasa.

5) Ijupu sistemụ mmiri gafere

6) Nkwado akụkụ.

Anyịnya ebu isi efere, ibughari ebu isi efere, kwushin ngọngọ (nzukọ, n'ọnọdu, echichi ọrụ).

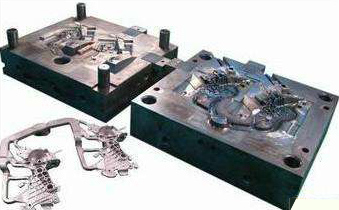

Ihe dị iche n’etiti ịkpụzi ebu na ịkpụzi plastik:

1. Ọnọdụ ogwu ogbugba nke anwụ anwụ bụ nnukwu. Ya mere, template kwesịrị ịdịtụ oke. Gbochie nrụrụ.

2. Onu-uzo nwuru ihe nkedo di iche na nke ogwu. Nnukwu nrụgide nke ihe eji eme ihe site na cone splitter.

3. Isi ihe nwuru anwu n’adighi anwu kwesiri. N'ihi na ọnọdụ okpomọkụ dị n'ime oghere karịrị 700 ℃. Ya mere, ịkpụzi nke ọ bụla dị ka otu quenching. Uji eze ga-esiwanye ike. Akpukpo ogwu ndi mmadu kwesiri ihichapu n'elu hrc52.

4. N'ozuzu, oghere nke ịnwụ-na-anwụ anwụ chọrọ ọgwụgwọ ọgwụgwọ nitriding. Gbochie alloy ka ọ ghara ịrapara na oghere ebu.

5. N'ozuzu, corrosion nke anwụ casting die bụ dịtụ nnukwu. Elu dị n'èzí n'ozuzu ya na-acha anụnụ anụnụ.

6. E jiri ya tụnyere ebu ntụtụ. Odabara nwechapụ nke ibughari akụkụ nke ndị nwụrụ anwụ mgbatị-anwụ (dị ka isi Anam Udeme mmịfe) kwesịrị ibu. N'ihi na elu okpomọkụ nke na-anwụ mgbatị usoro ga-eme thermal mgbasa. Ọ bụrụ na nwechapụ ahụ pere mpe, ebu ga-arapara.

7. Akụkụ nkewa nke ịnwụ anwụ na-anwụ nwere nnukwu ihe dabara adaba. Ebe ọ bụ na mmiri nke alloy dị mma karịa nke plastik, ọ dị oke egwu maka nnukwu okpomọkụ na ihe nrụgide dị elu na-efe efe site na nkewa.

8. Ọgwụ akpụzi na-adaberekarị na thimim. Enwere ike igosipụta akụkụ nkewa. The anwụ-mgbatị ebu ga-nyere na iyuzucha oghere na a slag achịkọta akpa (na-anakọta oyi ihe onwunwe isi).

9. Forkpụ ihe anaghị ekwe ekwe. Ọgwụ ọsọ nke na-anwụ ningfe ịkpụzi bụ ngwa ngwa. Nrụgide ịgba nke izizi. Plastic ebu na-emekarị kewara ọtụtụ ogwu ogbugba, nsogbu.

10. The anwụ-mgbatị ebu bụ abụọ efere ebu (Ahụbeghị m atọ efere anwụ-mgbatị ebu ugbu a) otu oghere. Ngwongwo ngwaahịa dị iche iche nke ebu ebu dị iche iche. 3 efere ebu bụ ndị nkịtị. Nọmba na usoro nke oghere na-ekwekọghị na-anwụ Ọdịdị. Square timbim na-adịghị eji na-anwụ mgbatị ebu. Sịlịnda.

11. Chọọ pin (elu okpomọkụ na ezi ihe ngwọta fluidity) dị mfe jam, nke na-eduga na-ejighị n'aka ebu mmepụta. Tụkwasị na nke ahụ, a na-eji nkedo plastik na ihe nkedo na-anwụ anwụ mee nke ígwè dị iche iche; plastic ebu n'ozuzu na-eji 45 × ígwè, T8, T10 na ndị ọzọ ígwè, mgbe anwụ-mgbatị

Mestech ụlọ ọrụ na-elekwasị anya na ubi nke nkenke ebu n'ichepụta na akụkụ mmepụta maka ihe karịrị afọ 10, na elu ụlọ ọrụ na nkà na ụzụ na ọgaranya ebu mmepụta ahụmahụ. Ngwaahịa nke ụlọ ọrụ ahụ bụ ngwaahịa plastik ma ọ bụ ihe shea dị ka ngwaahịa dijitalụ dijitalụ, ngwaọrụ ahụike, ngwaahịa ụmụaka, wdg, yana ngwaahịa plastik dị ka ngwaahịa ụlọ na akụkụ akpaaka. The ụlọ ọrụ nwere ike ike nke bughi imewe na ebu imewe, nke nwere ike inye ndị ahịa na ndị ọzọ kachasị aro na ngwaahịa Ọdịdị na ndị ọzọ ezi uche atụmatụ maka ebu