Nhazi ígwè (metalworking), bụ ụdị nhazi teknụzụ na mmepụta ihe nke imepụta isiokwu, akụkụ na akụrụngwa sitere na ihe igwe.

A na-ejikarị akụkụ ígwè dị iche iche na igwe na akụrụngwa dị iche iche. Metal akụkụ nwere akụkụ kwụsie ike, ike na ekweghị ekwe, elu na ala okpomọkụ na-eguzogide e ji mara na conductivity, nke na-eji mee ka nkenke akụkụ. E jiri ya tụnyere akụkụ plastik, e nwere ọtụtụ ụdị ihe maka akụkụ ọla, dị ka alloy alloy, alloy copper, zinc alloy, steel, titanium alloy, magnesium alloy, wdg, nwere ihe dị iche iche. N'ime ha, a na-ejikarị ferroalloy, alloy alloy, alloy alloy na zinc alloy na ụlọ ọrụ mmepụta ihe na ngwaahịa obodo. Ihe igwe ndị a nwere anụ ahụ na kemịkal dị iche iche, usoro dị iche iche na ọdịdị nke teknụzụ na-arụ ọrụ akụkụ nwere nnukwu ọdịiche.

Usoro nhazi kachasị nke akụkụ ígwè bụ: ịkpụzi, ịkpụcha, nkedo nkenke, ntụ ntụ, ịkpụzi ígwè.

Machining bụ usoro nke na-agbanwe n'ozuzu akụkụ ma ọ bụ arụmọrụ nke workpiece site a ụdị n'ibu akụrụngwa. Dịka ọdịiche dị na usoro nhazi, enwere ike kewaa ya na ịkpụ na nrụgide nrụgide. Stamping bụ ụdị akpụ usoro nhazi nke na-eji pịa ma nwụọ iji tinye ike mpụga na mpempe akwụkwọ, warara, ọkpọkọ na profaịlụ iji mepụta nrụrụ plastik ma ọ bụ nkewa, iji nweta ọdịdị achọrọ na ogo nke ọrụ (akụkụ zọọ).

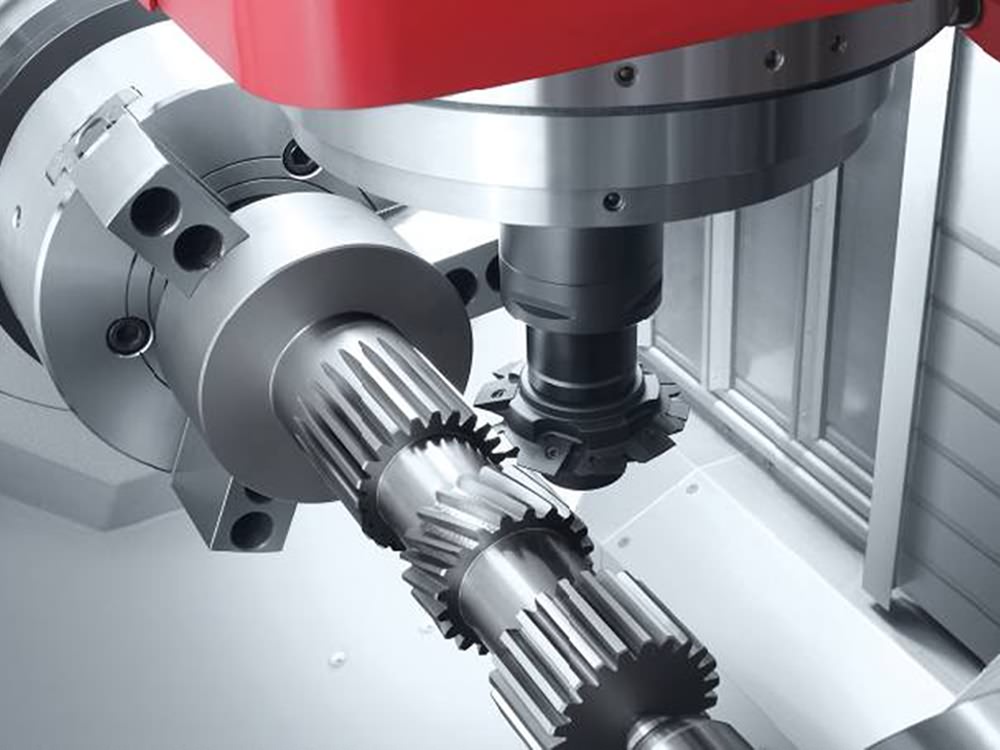

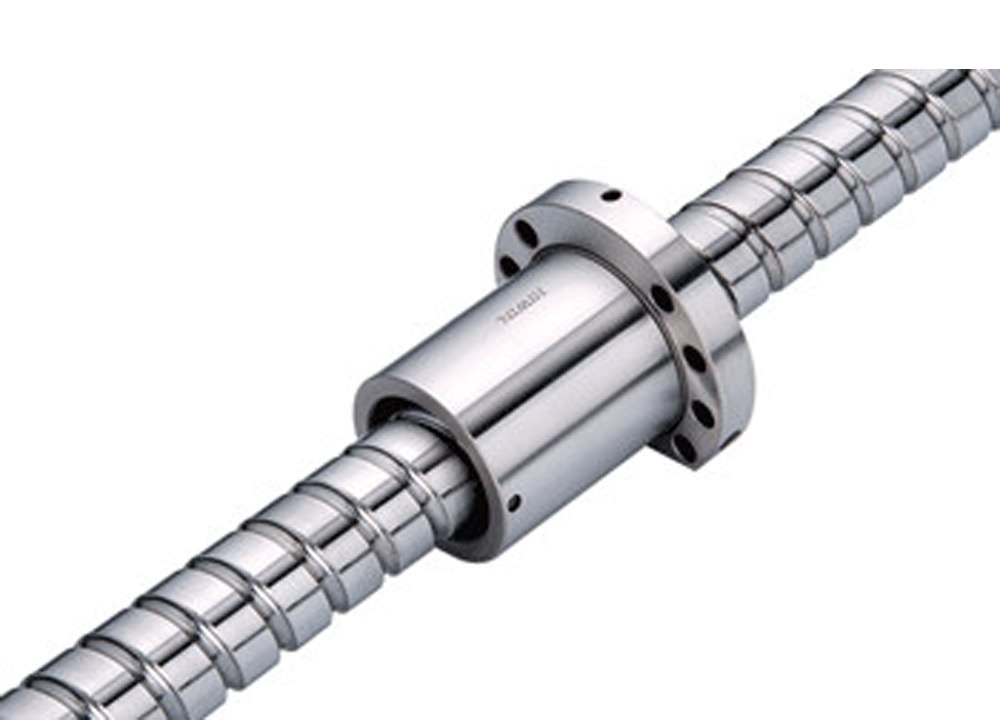

Nkenke mgbatị, powder nkà mmụta banyere ígwè na metal injection ịkpụzi nke na-ekpo ọkụ na-arụ ọrụ usoro. A na-etolite ha n'ime oghere ebu site na ikpo oku ọla a wụrụ awụ na nnukwu okpomọkụ iji nweta ọdịdị na nha achọrọ. Enwekwara mpempe ihe puru iche, dika: laser machining, EDM, ihe nkpuchi ultrasonic, igwe onyonyo, ihe eji eme ihe na ngwa ngwa. Na-atụgharị, na-egwe ọka, ibe ya bụrụ, mgbatị, egweri, CNC machining, CNC machining. Ha nile bu ime ihe igwe.

Ngwaọrụ igwe maka ịhazi igwe

Ngwaọrụ igwe maka ịhazi igwe

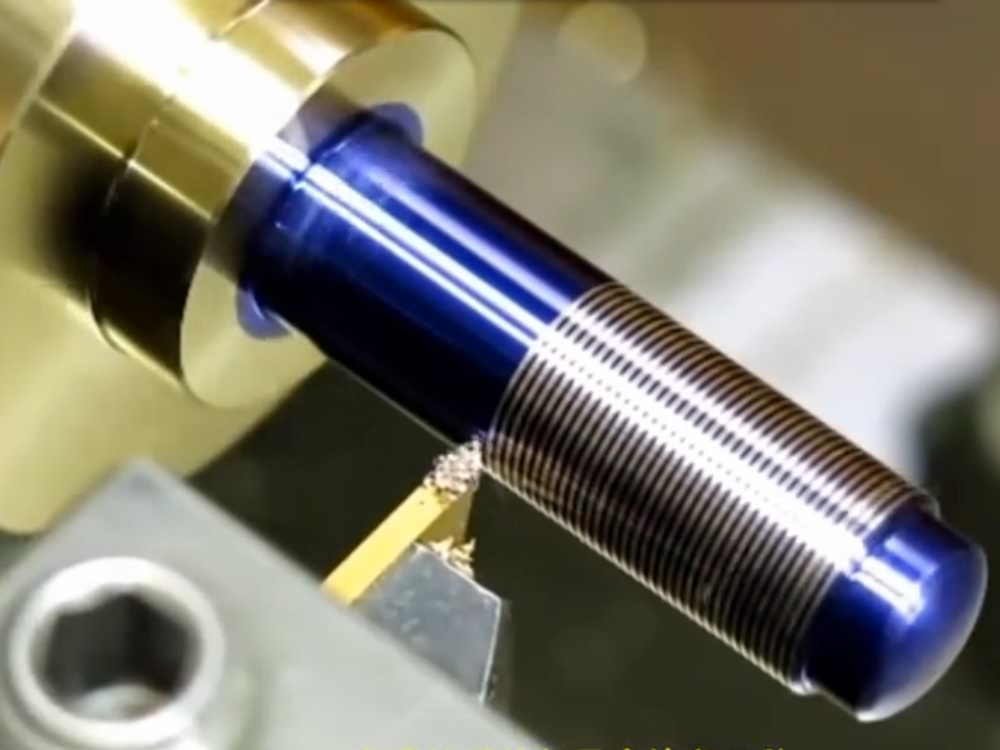

Ọdọ machining - Center lathe

Ọdụdọ orùrù machining -EDM

Nkenke ịghasa machining

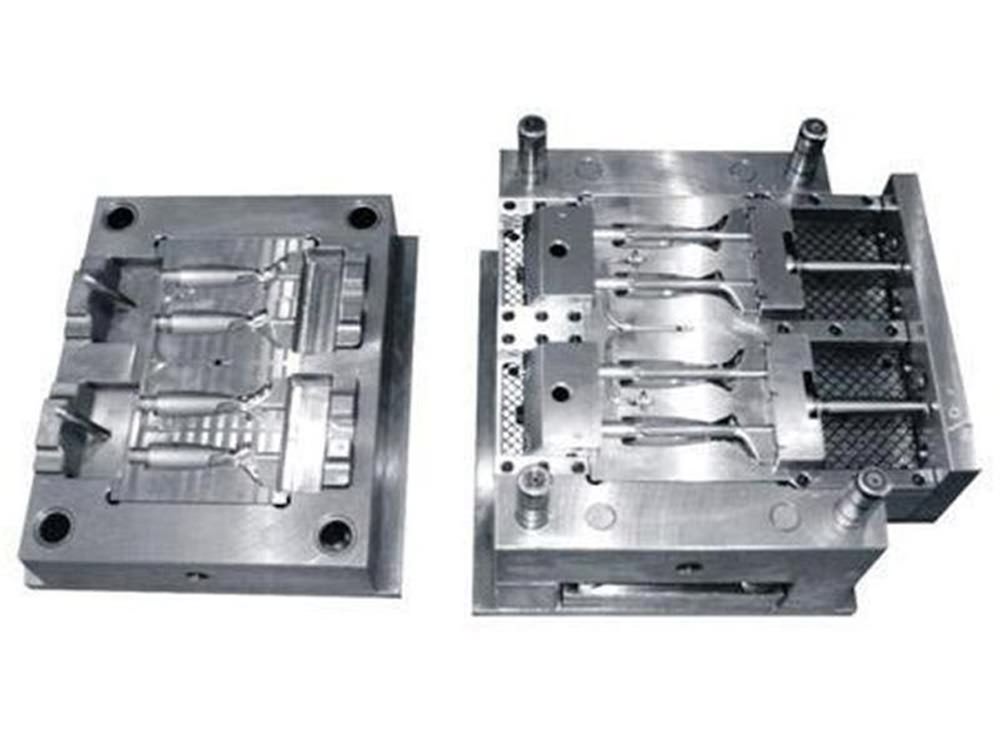

Die mgbatị igwe

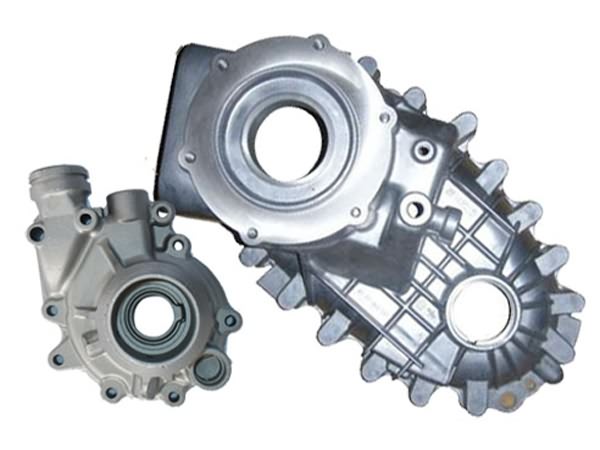

Die casting nwụọ

Punching igwe

Stamping anwụ

Ngosipụta nke akụkụ ọla:

1. Ferrous metal akụkụ: akụkụ mee nke ígwè, chromium, manganese na ha alloy ihe.

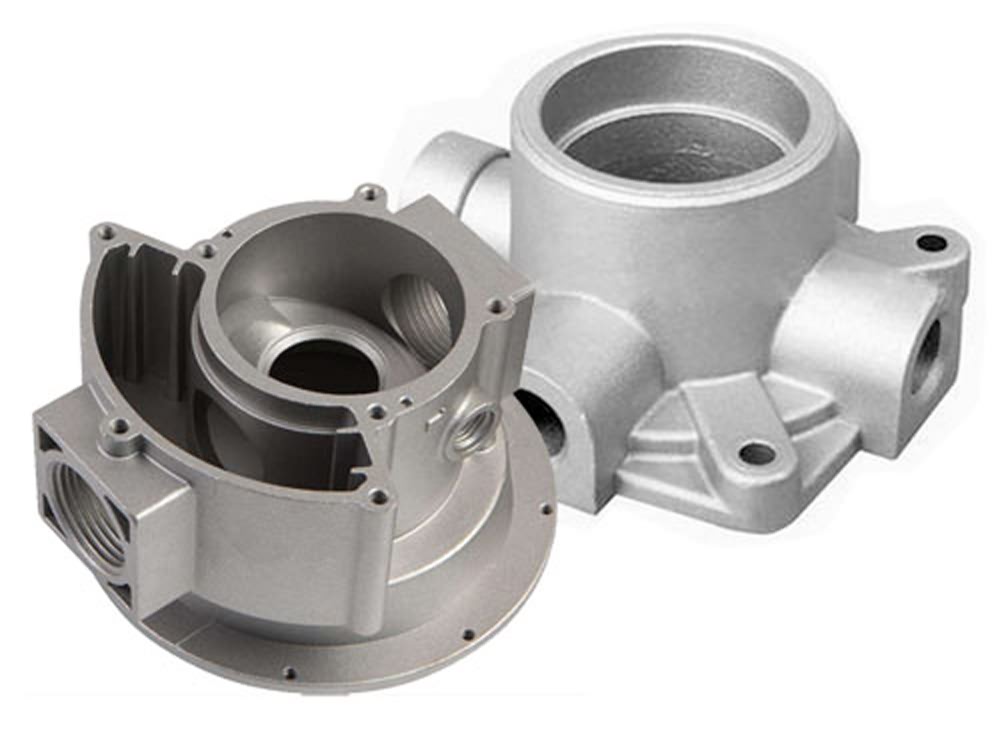

Nkenke ebu akụkụ

CNC machined ígwè akụkụ

Nkenke ụzọ ịghasa

Gear nnyefe akụkụ

2. Ngwongwo ndi na-achoghi acho acho: ihe ndi ozo na-achoghi dika alloy alloy, alloy alloy, allones magnesium, nickel alloy, tin alloy, tantalum alloy, titanium alloy, zinc alloy, molybdenum alloy, zirconium alloy, wdg.

Ngwongwo ọla

Zinc anwụ mgbatị ụlọ

Aluminom zọ cover

Aluminom anwụ mgbatị ụlọ

Enwere ike ikewa ọgwụgwọ ihu na akụkụ anọ

1. Mechanical elu ọgwụgwọ: sandblasting, shot ọgbụgba ọkụ, polishing, Rolling, polishing, brushing, spraying, sere, oiling, wdg

2. Chemical elu ọgwụgwọ: bluing na blackening, phosphating, pickling, electroless plating nke dị iche iche ọla na alloys, td ọgwụgwọ, QPQ ọgwụgwọ, chemical ọxịdashọn, wdg

3. Electrochemical n'elu ọgwụgwọ: anodic ọxịdashọn, electrochemical polishing, electroplating, wdg

4. Ngwọta ihu igwe nke oge a: ọgwụ ikuku mmiri CVD, ntinye ume nke anụ ahụ PVD, ntinye ion, ion plating, laser surface treatment, wdg.

Mestech na-enye ndị ahịa atụmatụ na imepụta ọrụ maka akụkụ igwe gụnyere nchara, alloy alloy, zinc alloy, copper alloy and titanium alloy. Biko kpọtụrụ anyị ma ọ bụrụ na ọ dị mkpa.