Nhazi ọkwa

Nkọwa nkenke:

Ebu (ebu, nwụọ) bụ nnukwu ezinụlọ, ọ na-arụ ọrụ dị mkpa na ụlọ ọrụ ọgbara ọhụrụ. Nhazi ọkwa doro anya dị ezigbo mkpa iji ghọta mmepụta ụlọ ọrụ mmepụta ihe.

Ebu (ebu, nwụọ) bụ ngwa ọrụ pụrụiche eji eme ihe n'ọrụ mmadụ. Nhazi ọkwana-agụnye a dịgasị iche iche. Na oge a, ochie nwere njikọ chiri anya na ụlọ ọrụ mmepụta ihe, nke na-eme ka arụmọrụ mmepụta na nkenke nke akụkụ dịkwuo mma.

Ebu bu ngwa oru puru iche nke eji eme ihe ndi mmadu. Nhazi ọkwa ebu gụnyere ọtụtụ ihe. Na oge a, ebu nwere njikọ chiri anya na nrụpụta ụlọ ọrụ mmepụta ihe, nke na-eme ka arụmọrụ mmepụta na nkenke nke akụkụ dịkwuo mma.

Ebu bụ akụrụngwa nke teknụzụ nke na - akpụzi ihe dị iche iche na ngwaahịa yana akụkụ ya na nha ya. Gụnyere: zọ anwụ, plastic injection ebu, anwụ ningfe ebu, ibe ya bụrụ ebu, powder powder metallurgy die ebu, ịbịaru anwụ, extrusion anwụ, inyefe anwụ, iko anwụ anwụ, roba ebu, seramiiki ebu, mgbatị ebu na ndị ọzọ na ụdị. Na ụlọ ọrụ nke oge a, ebu na -atakarị ebu eji mee otutu arụ akụkụ plastik na akụkụ ngwaike. Mgbe ejiri ya mepụta ihe siri ike site na rọba mmiri mmiri, igwe na ihe ndị ọzọ etinyere n'ime oghere ya, anyị na-akpọ ya "ebu" ma ọ bụ "ebu". Mgbe a na-eji ya ọkpọ, ekwe, ekwe na extrusion nke siri ike oghere, anyị n'ozuzu na-akpọ ya a "anwụ".

A na-ekepụta ihe ebu site na njirimara ya dị ka ndị a:

Nhazi site na ihe na teknụzụ nhazi, na Ebu nwere ike kere n'ime ngwaike anwụ ebu, plastic ebu na pụrụ iche ebu.

(1) Ihe na-abụghị ọla na ntụ na-akpụ akpụ akpụ akpụ akpụ akpụ akpụ akpụ akpụ akpụ akpụ akpụ akpụkọ akpụkọ: nkụkọ plastik, akpụgharị sintering, ebu aja, akpụ akpụ agụụ na ebu paraffin.

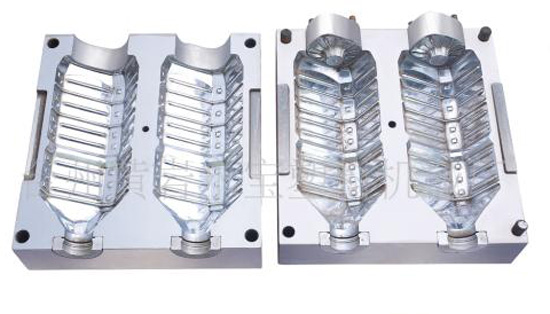

Na mmepe ngwa ngwa nke plastik polymer, ebu ebu nwere njikọ chiri anya na ndụ ndị mmadụ. A na-ekezi ebu ebu na: ịkpụzi ebu, ngwa ngwa extrusion, ebu ebu aka gas, wdg.

(2) Akụrụngwa akụrụngwa kewara: ịnwụ anwụ nwụọ, zọọ stam (dịka ịkụ ọkpọ nwụrụ, ịgbu anwụ, ịbịaru nwụrụ, ịtụgharị nwụrụ, ịda mba nwụrụ, ịda mba nwụrụ, ịkọ ihe nwụrụ, ịkpụ anwụ, wdg) dị ka ịnwụ anwụ nwụrụ, iwe iwe nwụrụ, wdg), extrusion na-anwụ, ịnwụ anwụ nwụọ, ibe ya anwụ, wdg.

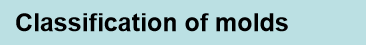

Metal zọ anwụ

1.Classification nke ebu ebu

(1) Ọgwụ akpụzi

Ọgwụ ebu bụ ụdị ebu eji akpụ akụkụ nke thermoplastic na thermosetting plastik. Ọgwụ na ịkpụzi na ọtụtụ-eji n'ihi na nke elu nkenke na arụmọrụ. Ọgwụ na ịkpụzi bụ ịgbakwunye plastic n'ime kpo oku gbọmgbọm nke injection igwe. A na-eme ka plastic dị ọkụ ma gbazee. N'ịbụ onye ihe nkedo ma ọ bụ ihe nkedo nke igwe ogwu ahụ na-akwagharị, plastik ahụ gbanye n'ime oghere ahụ site na ntanye na usoro ịwụnye ebu, na-esi ike ma na-akpụzi n'ime ngwaahịa ọgwụ ahụ n'ihi omume anụ ahụ na nke kemịkal. Ọgwụ na ịkpụzi bụ a okirikiri esịnede ogwu ogbugba, na-ejide mgbali (jụrụ) na demoulding usoro nke plastic parts.Therefore, Ọgwụ na ịkpụzi nwere oge ufodu àgwà.

Thermoplastic injection ịkpụzi nwere uru nke obere ịkpụzi okirikiri, elu mmepụta arụmọrụ, obere eyi nke wụrụ awụ ihe na ebu, na nnukwu ogbe nke plastic akụkụ na mgbagwoju udi, doro anya elu ụkpụrụ na akara, na elu akụkụ ziri ezi. Otú ọ dị, maka akụkụ plastik nwere nnukwu mgbidi mgbidi, ọ na-esiri ike izere ịkpụzi ntụpọ. Anisotropy nke akụkụ plastik bụkwa otu n'ime nsogbu nsogbu. Ekwesịrị ime usoro niile iji belata ya.

Ọgwụ ebu

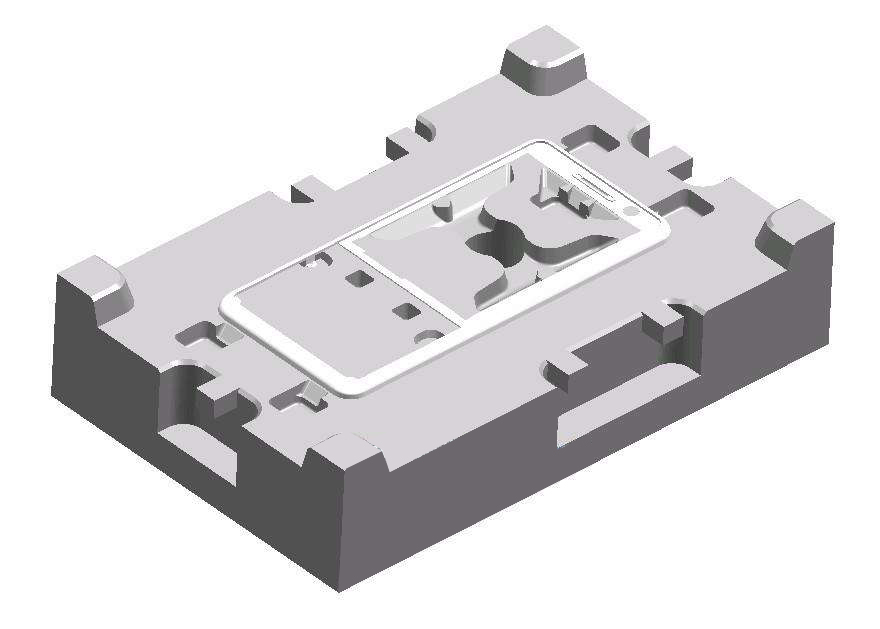

(2) ebu ebu maka plastik

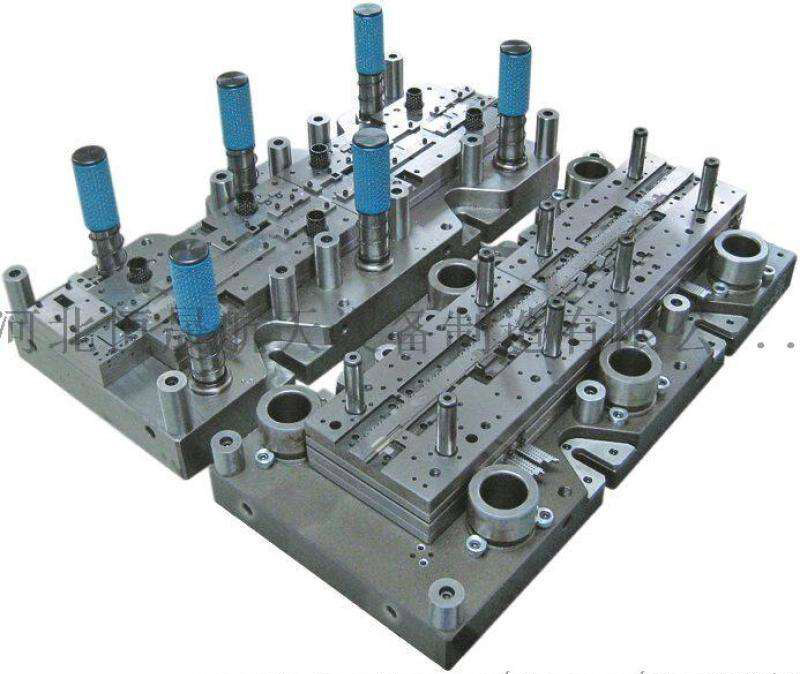

Plastic extrusion ịkpụzi bụ ụdị akpụ usoro na-eme ka plastic na viscous eruba ala gafere site na-anwụ na kpọmkwem cross-ngalaba udi na elu okpomọkụ na ụfọdụ nsogbu, na mgbe ahụ na-enwe ya na-aga n'ihu profaịlụ na chọrọ cross-ngalaba udi na ala okpomọkụ. Usoro mmepụta nke ịkpụzi extrusion bụ nkwadebe nke ihe ndị na-akpụzi, nkedo extrusion, ọnọdụ dị jụụ, traction na mbepụ, nhazi post nke ngwaahịa ndị amịpụtara (nhazi ma ọ bụ ọgwụgwọ okpomọkụ). Na usoro nke extrusion, ekwesịrị itinye uche maka ịhazigharị ọnọdụ okpomọkụ, ọsọ ọsọ na ọsọ ọsọ nke ngalaba ọ bụla na-ekpo ọkụ nke gbọmgbọm ma nwụọ nke onye na-eme ihe iji nweta profaịlụ extrusion ruru eru.

Ekwesiri ilebara anya nke oma imeghari onu ogugu nke polymer gbaputa site na onwu. N'ihi na mgbe ọnụego extrusion nke wụrụ awụ na-adị ala, ihe a na-akpọpụta nwere ọdịdị dị mma yana ọdịdị akụkụ obe, mana mgbe ọnụego extrusion nke ihe a wụrụ awụ ruru oke oke, elu ahụ ga-adị njọ ma tufuo ọfụma, na akpụkpọ anụ shark, oroma bee, udi distortion na ndị ọzọ na phenomena ga-apụta. Mgbe ọnụego extrusion na-abawanye n'ihu, a ga-agbagọ elu nke extrudate, ọbụnakwa na-agbaji ma gbajie n'ime iberibe agbaze ma ọ bụ cylinders. Ya mere, njikwa nke ọnụego extrusion dị ezigbo mkpa.

Plastic extrusion mmepụta akara

Extrusion nwụrụ

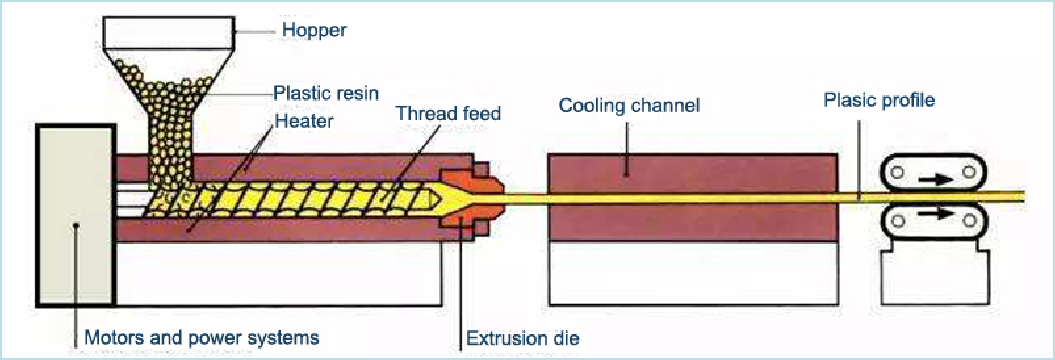

(3) Oghere na-akpụzi ebu

Oghere na-akpụ akpụ na-agụnye extrusion igbu ịkpụzi oghere na-akpụ na ọgwụ na-akpụzi oghere na-akpụ ụdị ebu abụọ.

Oghere na-akpụzi bụ ụdị usoro nhazi nke na-edozi tubular ma ọ bụ mpempe akwụkwọ oghere nke extrusion ma ọ bụ ogwu na-eme ma ka nọ na steeti plasticizing na ịkpụzi ebu ahụ, gbanye ikuku ikuku ozugbo, mee ka oghere ahụ gbasaa ma rapara na mgbidi nke mgbidi ahụ ebu oghere, na nwepu mgbe obi jụrụ na imecha ya, iji nweta ngwaahịa oghere achọrọ.

Ihe plastik kwesịrị ekwesị maka ịkpụzi oghere bụ akwa polyethylene, obere nrụgide polyethylene, isiike polyvinyl chloride, polyvinyl chloride dị nro, polystyrene, polypropylene, polycarbonate, wdg.Dị ka ụzọ dị iche iche nke parison si dị, oghere na-eme oghere nwere ike kee n'ime extrusion ịkpụzi ogwu igbu ịkpụzi. The uru nke extrusion igbu ịkpụzi oghere akpụ bụ na ihe owuwu nke extruder na extrusion igbu Ebu dị mfe. Ihe ọghọm ya bụ na ọkpụrụkpụ nke mgbidi parison ekwekọghị, nke na - akpata ngwa mgbidi na - adịghị agbanwe agbanwe nke ngwaahịa plastik. Okike ziri ezi bu ihe osise di iche iche nke ihe nkedo nke extrusion.

Ọgwụ igbu ịkpụzi nwere uru nke edo mgbidi ọkpụrụkpụ na-enweghị efe efe onu. N'ihi na ala nke ịkpụzi ọgwụ ahụ, ala nke ngwaahịa dị omimi agaghị emepụta nsị a na-agbapụta agbapụta, nke ọ bụghị naanị na ọ mara mma kamakwa ọ dị elu. Ihe ọghọm bụ na akụrụngwa na ebu ejiri dị oke ọnụ, yabụ usoro a na - ejikarị eme ihe na nrụpụta nke obere ihe ndị na - adịghị mma, ọ naghị ejikwa ya na ojiji nke extrusion igbu ịkpụzi oghere akpụ.

Ọgwụ igbu ịkpụzi maka plastic

Ebu ebu

(4) Anwụ na-akpụzi ebu maka plastik

Die casting Ebu na-akpọ nyefe ebu. A na-agbakwunye ihe plastik ahụ n'ime ụlọ nri na-eri nri, wee tinye nrụgide na kọlụm nrụgide. Plastik ahụ na-agbaze n'okpuru oke okpomọkụ na nrụgide, ma banye n'ime oghere site na usoro nkedo nke ebu, jiri nwayọọ nwayọọ na-esiwanye ike ma na-akpụ. Nke a na-akpụ usoro a na-akpọ na-anwụ-mgbatị akpụ, na ebu na-eji na-akpọ anwụ-mgbatị ịkpụzi. Nke a na ụdị ebu na-akasị ji maka thermosetting plastic akpụ.

(5) mkpakọ akpụzi

Mkpakọ ịkpụzi bụ otu n'ime ndị mbụ ịkpụzi ụzọ nke plastic akụkụ. Mkpakọ akpụ bụ itinye plastik ozugbo n'ime oghe anwụ uji eze na a ụfọdụ okpomọkụ, na mgbe ahụ na-emechi die. N'okpuru ihe nke ikpo ọkụ na nrụgide, plastik na-agbaze n'ime ala mmiri. N'ihi ihe anụ ahụ na nke kemịkal, a na-eme ka plastik sie ike n'ime akụkụ plastik nwere ụdị ụfọdụ na ogo na okpomọkụ ụlọ. Mkpakọ ịkpụzi tumadi iji na-akpụzi thermosetting plastik, dị ka phenolic ịkpụzi ntụ ntụ, urea formaldehyde na melamine formaldehyde ịkpụzi ntụ ntụ, iko eriri mesikwuru phenolic plastik, epoxy resin, DAP resin, silicone resin, polyimide na na. Ọ nwekwara ike ịkpụzi na nhazi unsaturated polyester aggregates (DMC), mpempe akwụkwọ ịkpụzi plastik (SMC), prefabrication. Monolithic ịkpụzi plastik (BMC) wdg N'ozuzu, kenha Ọdịdị nke elu na nke ala nwụrụ nke mkpakọ film a na-enwekarị enwe, na mkpakọ nwụrụ na-ekewa atọ ụdị: tojupụta ụdị, na-abụghị-ejupụta ụdị na ọkara-efefe ụdị.

(6) Nrụgide nrụgide na-anwụ

A makwaara dị ka nkedo na-anwụ anwụ. A na-agbakwunye ihe plastik ahụ n'ime ụlọ na-ebu ọkụ ọkụ, wee tinye kọlụm ịpị ahụ n'ime ụlọ nkwụ ụgwọ iji kpọchie ọnwụ. A na-etinye nrụgide ahụ na plastik site na kọlụm ịpị. Igwe plastik na-agbaze n'ime ala na-asọba na oke okpomọkụ na nrụgide dị elu, ma sie ike n'ime oghere dị nwayọ nwayọ site na usoro ịgba agba. Nke a na-akpụ usoro a na-akpọ nyefe ịkpụzi. Pressure injection ịkpụzi adabara siri ike plastik dị iche iche agbaze ihe. Onwere, ọ ga-eji maka mkpakọ ịkpụzi ma ọ bụ mgbali injection ịkpụzi. Otú ọ dị, mgbe ikpo ọkụ na-adịwanye ala karịa ọnọdụ ime ka ihe sie ike, ọnọdụ agbaze ahụ nwere ezigbo mmiri mmiri, na mgbe okpomọkụ dị elu dị elu, ọnụego nkwenye ahụ dị elu.

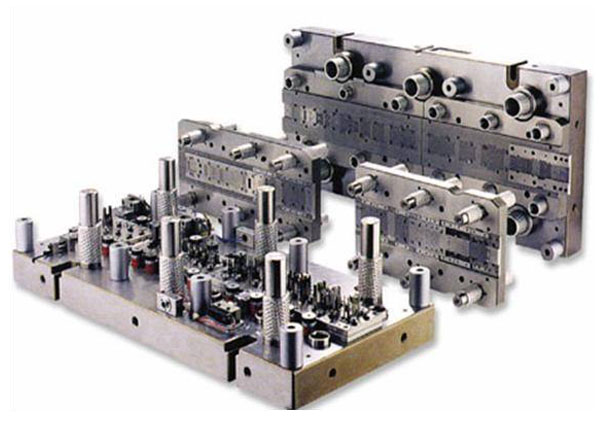

2. Nhazi nke ngwaike nwua

Dị ka akụrụngwa na usoro gburugburu ebe obibi, metal ebu nwere ike kere n'ime-ekpo ọkụ na-arụ ọrụ ebu na oyi na-atụ na-arụ ọrụ ebu. Ihe dị iche n’etiti ha bụ nnukwu.

1) Hot na-arụ ọrụ na-anwụ: na-ekpo ọkụ na-arụ ọrụ na-anwụ anwụ na-ezo aka na-anwụ anwụ kwesịrị ekwesị maka na-ekpo ọkụ deformation nke metal, dị ka na-ekpo ọkụ extrusion anwụ, na-anwụ mgbatị anwụ, na-ekpo ọkụ ibelata anwụ, na-ekpo ọkụ na-ewe iwe na-anwụ, wdg. na nrụgide dị elu ruo ogologo oge, ihe a na-anwụ anwụ chọrọ ka ọ nwee ike dị elu, ike na nkwụsi ike ọkụ, karịsịa ike ọkụ dị elu, ike ọgwụgwụ nke okpomọkụ, ike ike na iyi mgbochi. Ọ kachasị gụnyere:

A. Metal anwụ mgbatị anwụ ebu: usoro bụ igba elu-okpomọkụ wụrụ awụ mmiri mmiri metal n'ime ịnwụ oghere iji nweta chọrọ bughi akụkụ. Metal anwụ mgbatị a na-eji mee ka mgbagwoju udi akụkụ nke aluminum alloy, zinc alloy, magnesium alloy na ndị ọzọ na-abụghị ferrous alloys.

B. Ọla ntụ ntụ na-akpụ akpụ akpụ akpụ: usoro a bụ ime igwe ntụ ka ọ bụrụ otu ụdị na etu ijeri na ebu ahụ, wee kpoo ọkụ ahụ na ọnọdụ agbaze ya, ka e wee nwee ike ịmalite ya. A na-ejikarị sinal ntụ eme ihe maka igwe anaghị agba nchara, titanium, ọla kọpa, ígwè, nickel na akụkụ ndị ọzọ dị elu.

C. Metal na-ekpo ọkụ extrusion anwụ: na-ekpo ọkụ na-arụ ọrụ na-ekpo ọkụ extrusion anwụ bụ n'ozuzu na ọdabara na nhazi nke aluminom, magnesium, ígwè na ndị ọzọ ọla na elu okpomọkụ gburugburu ebe obibi, na obe ngalaba udi nke eme akụkụ-agbanweghi agbanwe. The na-ekpo ọkụ extrusion anwụ a chọrọ ka nwere ezi okpomọkụ na-eguzogide na-eyi na-eguzogide na tempering eguzogide.

Metal anwụ mgbatị ebu

Hot extrusion anwụ na aluminom profaịlụ

2) Cold na-arụ ọrụ nwụrụ (Stamping nwụrụ): arụ ọrụ oyi na-anwụkarị na-anwụ na-arụ ọrụ na okpomọkụ ụlọ, nke a na-akpọkarị stamping nwụrụ (dị ka ịkụ ọkpọ na-anwụ, ịwụ anwụ, ịbịaru nwụrụ, ịtụgharị nwụrụ, ịda mbà nwụrụ, ịtụgharị nwụrụ, bulging nwụrụ , ịkpụzi nwụrụ, wdg). Akụkụ na-arụ ọrụ nke oyi na-arụ ọrụ na-anwụ n'ozuzu kwesịrị ịnwe ọtụtụ nrụgide, ịgbagọ ike, mmetụta ike na esemokwu, yabụ nguzogide nrụrụ adịghị nnukwu.

A. Metal blanking anwụ: ndị metal blanking anwụ na-eji bee abụọ-akụkụ udi si metal efere. Enwere ike iji akụkụ dị ka oghere maka ekwe, ịbịaru na ịkpụ. Blanking na-bụ-eji maka blanking, punching na trimming nke ígwè, igwe anaghị agba nchara, aluminum alloy, ọla kọpa alloy na ndị ọzọ na efere.

B. Bending die: a akụkụ nke na-eji ọnwụ iji gbagọọ efere, Ogwe na ngalaba n'ime otu akụkụ, curvature and shape. O kwesịrị ekwesị maka nchara, igwe anaghị agba nchara, alloy alloy na ọla kọpa alloy.

C. Drawing die: ịbịaru bụ usoro nke zọọ, ịbịaru mgbanaka ma ọ bụ metal anwụ iji gbanwee mpempe akwụkwọ mpempe akwụkwọ n'ime cylinder ma ọ bụ akụkụ akụkụ igbe. Drawing anwụ bụ ngwa ọrụ eji ese ihe.

D. akpụ anwụ: iji anwụ anwụ akpụ bụ ụdị mmepụta usoro na plastic deformation na-rụrụ na ihe siri ike mgbe ya àgwà na ihe onwunwe ekike-agbanwe agbanweghi agbanwe. E. Riveting anwụ: metal riveting bụ usoro nke ijikọ abụọ workpieces site n'etiti workpieces site n'ibu ike. N'ozuzu, a na-eji riveting eme ihe n'etiti efere dị mbadamba. Ọnwụ ejiri mee ihe na usoro a na-akpọ riveting die.

Ekwe anwụ

Metal zọ anwụ

Iji ebu ma ọ bụ nwụọ:

(1). Ngwa electronic na nkwukọrịta;

(2). Ngwaọrụ Office;

(3). Omogbọala akụkụ ahụ mapụtara;

(4). Ngwa ụlọ;

(5) .Nke eletrik;

(6). Nlekọta ahụike na gburugburu ebe obibi;

(7). Facilitieslọ ọrụ mmepụta ihe;

(8) ọgụgụ isi;

(9). Gbọ njem;

(10). Ihe owuwu ụlọ, kichin na ụlọ mposi na akụrụngwa;