Plastic injection igwe

Nkọwa nkenke:

Mestech nwere 30 plastic injection ịkpụzi igwesite na 100 tọn ruo tọn 1500 na ndị ọkachamara nwere ọrụ 10 nwere ọrụ. Anyị nwere ike ịnye ọgwụ na ịkpụzi ngwaahịa dị iche iche nha maka ndị ahịa anyị

Plastic injection igwe na-akpọ ọgwụ ịkpụzi igwe ma ọ bụ injection igwe. Ọ bụ akụrụngwa kachasị na-eme ka plastik ma ọ bụ thermosetting plastic dị na ngwaahịa plastik nke ụdị dị iche iche site na iji ebu ebu plastik. Ọrụ nke ịkpụzi ọgwụ na-akpụnye plastik bụ ikpo plastik, tinye nrụgide dị elu na plastik a wụrụ awụ, ma mee ka ha gbaa ma jupụta oghere.

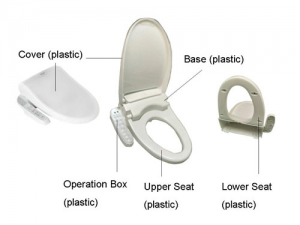

I-The nhazi ọkwa nke plastic injection ịkpụzi igwe Plastic injection ịkpụzi igwe nwere ikike ịkpụzi plastic ngwaahịa na mgbagwoju anya anya, kpọmkwem size ma ọ bụ ok udidi na metal inserts n'otu oge. A na-eji ya na nchekwa mba, electromechanical, automotive, njem, ihe ụlọ, nkwakọ ngwaahịa, ọrụ ugbo, ọdịbendị, agụmakwụkwọ, ahụike na ndụ ndị mmadụ kwa ụbọchị. Na mmepe ngwa ngwa nke ụlọ ọrụ plastik na usoro ihe mgbagwoju anya na ọrụ nke ngwaahịa na-akpụzi, ụdị dị iche iche na nkọwa nke ịkpụzi ọgwụ na -emepụta ngwa ngwa ka emepụtara. Dị ka nkenke nke ngwaahịa ndị e mepụtara, a ga-ekewa igwe ọgwụ na nkịtị na nkenke ọgwụ ịkpụzi. Dị ka ike na njikwa si dị, a na-ekewa igwe ọgwụ na-arụ ọrụ na igwe eletriki na igwe eletriki eletriki niile. Dị ka bughi ụdị injection ịkpụzi igwe, e nwere atọ iche iche: vetikal na kehoraizin (gụnyere abụọ na agba ọgwụ ịkpụzi igwe) na n'akuku ụdị.

Okwu mmalite maka njirimara nke igwe dị iche iche na-akpụzi

5. The n'ozuzu ebu-kpochidoro ngwaọrụ bụ na-emeghe gburugburu, mfe hazi nile di iche iche nke akpaka ngwaọrụ, adabara mgbagwoju, ọkaibe ngwaahịa nke akpaka ịkpụzi.

6. eriri belt conveyance ngwaọrụ dị mfe ịghọta na echichi n'etiti site ebu, ka ikwado akpaka mmepụta.

7. ọ dị mfe iji hụ na anọgidesi ike nke resin eruba na ebu okpomọkụ nkesa na ebu.

8. Onwem na n'usoro table, na-akpụ akpụ table na kpaliri table, ọ dị mfe ịghọta wet ịkpụzi na-anwụ anwụ Nchikota ịkpụzi.

9. obere ogbe ikpe mmepụta, ebu Ọdịdị dị mfe, ala na-eri, na mfe iwepụ.

10. vetikal igwe n'ihi na ala nke ike ndọda, dịtụ kehoraizin ala seismic eguzogide ka mma.

1.Horizontal injection ịkpụzi igwe

1.Ọ bụrụgodi na mainframe dị ala n'ihi obere fuselage ya, enweghị mmachi dị elu na osisi.

2.the ngwaahịa nwere ike na-ada na-akpaghị aka, na-enweghị ojiji nke n'ibu aka, akpaka ịkpụzi nwekwara ike nweta.

3.mme ka obere fuselage, nri na-adaba adaba, mmezi di mfe.

4.mold ga-arụnyere site kreenu.

5.multiple yiri ndokwa, na-akpụzi ngwaahịa dị mfe ịnakọta na mkpọ si ebu belt.

2.Vertical injection ịkpụzi igwe

1. ngwaọrụ ntụtụ na clamping ngwaọrụ dị n'otu vetikal centerline, na anwụ na-emeghe ma mechie tinyere elu na ala ntụziaka. Mpaghara ala ya bụ naanị ihe dịka ọkara nke igwe kwụ ọtọ, yabụ ntụgharị gaa na mpaghara mmepụta nke ihe dị ka okpukpu abụọ na mmepụta.

2. mfe imeta wet ịkpụzi. N'ihi na elu ịnwụ dị elu, ntinye dị mfe ịchọta. The akpaka wet ịkpụzi nwere ike mfe ghọtara site n'ịkpa ụdị nke igwe na ala template ofu na elu template ibughari na Nchikota nke

onye na-ebu belt na onye na-eme ihe.

3. E meghere ibu nke onwu ma mechie elu na ala site na nkwado nke uzo di ala. Ihe omume na enweghi ike imeghe ma mechie mpempe akwụkwọ ahụ n'ihi ntụgharị ihu na-akpata nke ike ndọda nke ịnwụ yiri igwe akụrụngwa agaghị eme. Ọ na - enyere aka imezi usoro igwe na ịnwụ.

4. Site na njikwa dị mfe, enwere ike wepu oghere ọ bụla, nke na-enyere aka ịkpụzi nkenke.

3.Double ọgwụ ịkpụzi igwe

Nwere ike ịmịnye agba abụọ oge na-akpụzi agba abụọ nke igwe na-akpụzi ọgwụ, nwere ike izute ihe ndị ahịa chọrọ maka ọdịdị, ndị ọrụ nwere ike iji ngwaahịa ahụ ka mma.

4.All igwe ogwu na-ekpochapu eletriki

Igwe ọkụ a na-agbanye ọkụ eletrik niile nwere ike ọ bụghị naanị igbo mkpa nke ngwa pụrụ iche, mana nwekwara uru karịa igwe ịkpụzi ọgwụ nkịtị.

Uru ọzọ nke igwe na -emepụta ọgwụ na -emepụta ọkụ eletrik bụ na ọ na-ebelata mkpọtụ, nke na-abaghị uru naanị ndị ọrụ, kamakwa ọ na-ebelata itinye ego na ụlọ ọrụ mmepụta ụda.

5.Angle injection ịkpụzi igwe

Akụkụ nke nkedo nkedo nke akuku nkedo na-akpụzi akụrụngwa dị n'akụkụ akụkụ na-agagharị agagharị nke usoro nhazi usoro, uru na ọghọm ya dị n'etiti vetikal na kwụ. Ebe ọ bụ na ntụziaka nkedo na akụkụ nke nkedo na-adị n'otu ụgbọelu ahụ, igwe na-akpụzi nkuku nkuku dị mma maka ebu na mgbatị asymmetrical nke ọnụ ụzọ ámá ma ọ bụ ngwaahịa ndị ụlọ ọrụ na-adịghị ekwe ka akara ọnụ ụzọ ámá.

6.Multi ojii ịkpụzi igwe

Ngwaọrụ ogwu na ihe nkedo nwere ihe abụọ ma ọ bụ karịa na-arụ ọrụ, yana ngwaọrụ ntụtụ na ngwaọrụ ahụ nwere ike ịhazi ya n'ọtụtụ ụzọ.

Ugbu a, atọ iche iche nke ọgwụ ịkpụzi igwe na-ọtụtụ-eji:

Kwụ injection ịkpụzi igwe na ọtụtụ-eji n'ihi na nke obere ohere, adaba echichi na mbara ngwa nso. Ugboro abụọ injection ịkpụzi igwe na-akasị ji maka akara na waterproofing chọrọ nke electronic ngwaahịa, ujo buffering eletriki ngwaọrụ, na ngwaahịa na a dịgasị iche iche na agba na kọmpat Ọdịdị. All-electric ọgwụ ịkpụzi igwe na-eji na mmepụta nke nnukwu iwu, elu nkenke obere na-ajụ-sized akụkụ.

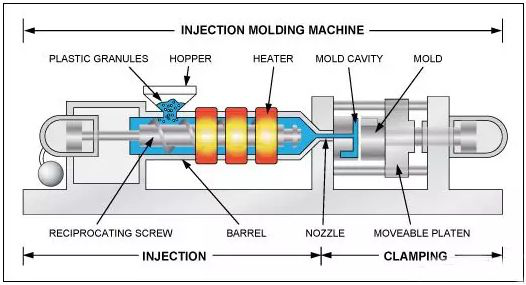

II-Kedụ ka igwe ọrụ ịkpụ ọkpọ plastik si arụ ọrụ?

Workingkpụrụ ọrụ nke igwe na-akpụzi ọgwụ yiri nke sirinji ọgwụ. Ọ bụ usoro teknụzụ nke ịgbanye plastik a wụrụ awụ (ntụgharị viscous flow) n'ime oghere mechiri emechi site na ntinye nke ịghasa (ma ọ bụ ihe ndozi) ma nweta ngwaahịa ahụ mgbe ọ gwọchara ya.

Ọgwụ na ịkpụzi bụ a cyclic usoro, onye ọ bụla okirikiri tumadi na-agụnye:

Quantitative feed - agbaze plasticization - mgbali ogwu ogbugba - jụrụ - ebu oghere na-ewere akụkụ. Wepu akụkụ plastik wee mechie ebu maka usoro ọzọ.

Ọgwụ na ịkpụzi igwe ọrụ ihe: Ọgwụ na ịkpụzi igwe na-arụ ọrụ ihe gụnyere njikwa keyboard arụ ọrụ, usoro njikwa eletriki na usoro hydraulic na-arụ ọrụ nke akụkụ atọ. Nhọrọ nke usoro ịgba ntụtụ, inye nri, ntụtụ ntụtụ, ọsọ ntụtụ, ụdị ọpụpụ, nlekota ọnọdụ ọ bụla nke gbọmgbọm ahụ, nrụgide ọgwụ na nrụgide nrụgide azụ ka emere n'otu n'otu.

Usoro izugbe nke nkedo ịkpụzi ịkpụzi igwe bụ: nke mbụ, a na-agbakwunye granular ma ọ bụ ntụ ntụ plastik n'ime gbọmgbọm ahụ, a na-agbaze plastik site na ntụgharị nke ịghasa na ikpo ọkụ nke mgbidi dị n'èzí. Mgbe ahụ, igwe ahụ na-eme ka ebu na oche ogwu na-aga n'ihu, nke mere na ọnụ ahụ dị nso n'ọnụ ụzọ nke ebu ahụ, wee wụsa mmanụ nrụgide ahụ n'ime cylinder ogwu iji mee ihe ahụ. A na-agbanye mkpanaka ahụ n'ihu ka agbaa agbaze ahụ n'ime mechiri emechi na-enwe obere okpomọkụ na nnukwu nrụgide na oke ọsọ. Mgbe oge ụfọdụ na nrụgide ijide (nke a makwaara dị ka njide nrụgide) na obi jụrụ, agbazere agbaze na-agbanwe ma kpụzie, enwere ike wepụta ngwaahịa a (ebumnuche ijide nrụgide bụ iji gbochie reflux nke gbazee na oghere ma nyekwa ya ihe eji abanye ebe ahụ ma hụkwa na ngwaahịa a nwere ụfọdụ njupụta na oke nha. Ihe ndị bụ isi dị mkpa maka ịkpụzi ọgwụ bụ plasticization, injection na ịkpụzi.Plasticization bụ ihe ebumnuche iji nweta ma hụ na ogo nke ngwaahịa ịkpụzi, yana iji mezuo ihe nkedo a choro, ogwu agha gha achoputa nsogbu na ngwa ngwa. N'otu oge ahụ, n'ihi na nrụgide ahụ dị nnọọ elu, nke kwekọrọ na nnukwu nrụgide n'ime oghere (nkezi mgbali dị n'ime oghere dị n'etiti 20 na 45) MPa), yabụ enwere ike ịmachi ike.Enwere ike ịhụ na ngwaọrụ ntụtụ na ngwa ijikọta bụ akụkụ bụ isi nke igwe ịkpụzi ọgwụ.

Ihe nyocha nke ngwaahịa plastik na-agụnye akụkụ atọ: nke mbụ bụ ọdịdị ọdịdị, gụnyere iguzosi ike n'ezi ihe, agba, luster, wdg; nke abụọ bụ izi ezi n’etiti nha na ọnọdụ metụtara; nke atọ bụ ihe anụ ahụ, kemịkal na eletriki kwekọrọ na ojiji. Ihe ndị a chọrọ dị iche iche dịka oge dị iche iche nke ngwaahịa ahụ. Ihe ntụpọ nke ngwaahịa ndị ahụ na-edina na imewe, nkenke na ogo ogo nke ebu. Mana n'eziokwu, ndị ọrụ ntanetị na-arụ ọrụ plastik na-ata ahụhụ mgbe mgbe site na ọnọdụ siri ike nke iji usoro teknụzụ iji dozie nsogbu nke nsogbu ntụ na-akpata ma nwee obere mmetụta.

Ngbanwe nke usoro bụ ụzọ dị mkpa iji melite ogo na mmepụta nke ngwaahịa. N'ihi na usoro ogwu ahụ dị mkpụmkpụ,

ọ bụrụ na anaghị achịkwa ọnọdụ usoro ahụ nke ọma, ngwaahịa mkpofu ga-aga n'ihu. Mgbe ị na-agbanwe usoro ahụ, ọ kachasị mma ịgbanwe naanị otu ọnọdụ n'otu oge ma lebe ya ọtụtụ oge. Ọ bụrụ na nrụgide ahụ, ọnọdụ okpomọkụ na oge dị n'otu ma gbanwee, ọ dị mfe ịme ọgba aghara na nghọtahie. Enwere ọtụtụ ụzọ na ụzọ iji dozie usoro ahụ. Dịka ọmụmaatụ, e nwere ihe karịrị ụzọ iri ngwọta dị iche iche maka nsogbu nke ọgwụ anaghị enye afọ ojuju nke ngwaahịa. Naanị site na ịhọrọ otu ụzọ isi abụọ ma ọ bụ abụọ iji dozie oke nsogbu nke nsogbu ahụ ka anyị nwere ike idozi nsogbu ahụ. Na mgbakwunye, anyị kwesịrị ị paya ntị na mmekọrịta olumba na azịza ya. Dịka ọmụmaatụ: ngwaahịa ahụ nwere ịda mbà n'obi, mgbe ụfọdụ iji bulie okpomọkụ ahụ, mgbe ụfọdụ iji belata ihe ọkụ ọkụ; mgbe ụfọdụ iji mee ka ihe dịkwuo elu, mgbe ụfọdụ iji belata ihe onwunwe. Ghọta ikweta na ọ ga-ekwe omume idozi nsogbu ahụ site na iji usoro ọzọ.

III-The isi oru parameters nke injection ịkpụzi igwe na-

Mmechi ike, kacha ntụtụ olu, kacha na kacha nta anwụ ọkpụrụkpụ, ebu ịgbanwe ọrịa strok, anya n'etiti esiri mkpara, ejection ọrịa strok na ejection mgbali, wdg

Nka na ụzụ chọrọ maka ọgwụ ịkpụzi igwe adabara maka ịkpụzi ngwaahịa nwere ike họrọ dị ka ndị a:

1 Clamping ike: ngwaahịa ntule ebe ba uba site ebu oghere mgbali erughị clamping ike, P hà ma ọ bụ hà QF uji eze nsogbu;

2 Oke ogwu kachasị: ibu ngwaahịa <oke nha ogwu. Ibu ahia = oke ogwu ogwu * 75 ~ 85%.

3 Ọgwụ na ịkpụzi igwe ebu ọkpụrụkpụ: agbata n'etiti kacha na kacha nta uru nke ọgwụ ịkpụzi igwe na ihe abụọ. Ebu kacha ọkpụrụkpụ injection ịkpụzi igwe na-erughị karịa kacha ebu ọkpụrụkpụ ebu. The kacha nta ọkpụrụkpụ bụ hà na nke kacha nta ebu ọkpụrụkpụ nke ọgwụ ịkpụzi igwe.

4 Ebu ebu: ebu oghere oghere = ebu ọkpụrụkpụ + ngwaahịa elu + ejection anya + ngwaahịa ohere. Nke ahụ pụtara, ebu-ebu anya.

5 Ebe dị anya n’etiti mkpara: nke ahụ bụ ịwụnye ọnọdụ ebu; ebu ogologo * obosara bụ ihe na-erughị esiri mkpara anya.

6 Ejection stroke na mgbali: ngwaahịa ejection distance na mgbali <ejection stroke na mgbali nke injection ịkpụzi igwe.

Usoro na ntinye nke igwe ogwu

Ọgwụ na ịkpụzi igwe na-emekarị mejupụtara ọgwụ usoro, ebu mmechi usoro, haịdrọlik nnyefe usoro, eletriki akara usoro, mmanu usoro, kpo oku na obi jụrụ usoro, nchekwa nlekota oru usoro na na.

Ọgwụ usoro

Ọrụ nke usoro ntụtụ: Usoro ntanye bụ otu n'ime akụkụ kachasị mkpa nke ịkpụzi ịkpụzi ọgwụ, n'ozuzu enwere ụzọ atọ dị mkpa nke ntanye, ịghasa, ịghasa ọgwụ ntanye plastik. Mostdị a na-ejikarị eme ihe bụ ịghasa. Ọrụ ya bụ ịgbanye plastik a wụrụ awụ n'ime oghere ebu site na ịghasa nrụgide na ọsọ ọsọ mgbe ọ fụsịrị plastik ụfọdụ ego na oge akọwapụtara na usoro nke igwe ọgwụ. Mgbe ogwu nchara, ihe gbazee a gbanyere n'ime oghere ebu ka edobere.

Usoro ogwu ogwu nwere ihe plasticizing na ngwaọrụ inyefe ikike.

The plasticizing ngwaọrụ nke ịghasa injection ịkpụzi igwe na-tumadi mejupụtara nri ngwaọrụ, gbọmgbọm, ịghasa, mama agafe akụrụngwa na nozulu. Ngwa nnyefe ike gụnyere cylinder ogwu, cylinder na-akpụ akpụ nke oche ogwu na ngwaọrụ ịghasa (a

Ebu clamping usoro

The ọrụ nke clamping usoro: ọrụ nke clamping usoro bụ iji hụ na ebu emechi, imeghe na ịkpọpụ ngwaahịa. N'otu oge ahụ, mgbe emechiri ebu ahụ, enyere ike ịmachi ihe iji gbochie nrụgide nke oghere ebu site na plastik gbazee na-abanye n'ime oghere ebu ahụ, ma gbochie ihe mkpuchi ahụ, na-ebute ọnọdụ ọjọọ nke ngwaahịa ahụ.

Ihe mejupụtara nke usoro clamping: usoro clamping na-ejikarị arụ ọrụ ngwaọrụ, usoro ntanye, usoro mmezi, ịkwapụ usoro, usoro ihu na azụ na-aga n'ihu, na-akpụ akpụ template, clamping cylinder na usoro nchedo nchekwa.

Hydraulic usoro

Ọrụ nke usoro nnyefe nke hydraulic bụ inye ike maka igwe na-akpụzi ọgwụ dịka ọrụ dịgasị iche iche nke usoro ahụ chọrọ, na iji mezuo ihe a chọrọ nke nrụgide, ọsọ na ọnọdụ okpomọkụ nke akụkụ dị iche iche nke igwe na-akpụzi ọgwụ. Ihe mejuputara ya bu ihe di iche iche nke hydraulic na ihe ndi ozo nyere aka, nke mmanu mmanu na moto bu ike nke ogwu. Valdị valves dị iche iche na-achịkwa nrụgide mmanụ na ọnụọgụ mmiri, ka ị wee nwee ike ịchọta usoro chọrọ ịkpụzi ọgwụ.

Usoro nchịkwa eletrik

Njikwa ezi uche dị n'etiti usoro nchịkwa eletriki na usoro hydraulic nwere ike ịghọta usoro chọrọ (nrụgide, ọnọdụ okpomọkụ, ọsọ, oge) na mmemme mmemme dị iche iche nke igwe ọgwụ. Ejiri ngwa eletriki mejuputara ya, ihe ndi elektrọnik, ngwa (lee ala aka nri), ndi na-ekpo oku, ihe mmetụta na ihe ndi ozo. N'ozuzu, e nwere ụzọ anọ nke njikwa, akwụkwọ ntuziaka, ọkara akpaka, akpaka ma gbanwee.

Heating / jụrụ usoro

A na-eji usoro kpo oku kpo oku na gbọmgbọm ahụ. Gbọmgbọm ahụ nke na-akpụzi ọgwụ na-ejikarị eriri ọkụ ọkụ eletrik eme ihe dị ka ngwaọrụ kpo oku, nke arụnyere n'èzí gbọmgbọm ahụ ma na-ekewa ya na thermocouple. Okpomọkụ na-enye okpomọkụ maka ihe plasticization site na mgbidi mgbidi mgbidi; obi jụrụ usoro a na-akacha eji ajụkwa mmanụ okpomọkụ, oke mmanụ dị elu ga-eme ka ọtụtụ mmejọ, ya mere a ghaghị ịchịkwa okpomọkụ mmanụ. Ebe ọzọ a ga - eme ka mmiri dị jụụ dị nso n'ọdụ ụgbọ mmiri nke ọkpọkọ nri iji gbochie akụrụngwa ịgbaze n'ọdụ ụgbọ mmiri ahụ, na - akpata ihe akụrụngwa enweghị ike inye nri nke ọma.

Lubrication usoro

Lubrication usoro bụ sekit nke na-enye ọnọdụ mmanu maka akụkụ ndị na-akpụ akpụ nke igwe na-akpụzi ọgwụ, dị ka template na-agagharị, na-agbanwe ngwaọrụ, na-ejikọ mgbanaka mkpịsị na okpokoro agbapụ, iji belata ike oriri ma melite ndụ nke akụkụ. Lubrication nwere ike ịbụ ma ọ bụ mmanu ejiri aka mee mgbe niile ma ọ bụ mmanụ eletrik na-akpaghị aka.

Usoro nlekota oru nchedo

Ngwaọrụ nchekwa nke ịkpụzi igwe na-arụ ọrụ iji chebe ndị mmadụ na ngwaọrụ nchekwa igwe. Karịsịa site n'ọnụ ụzọ nchekwa, nsogbu nchekwa, valvụ hydraulic, mgba ọkụ ịgba, ihe nchọpụta foto na ihe ndị ọzọ, iji nweta eletriki - Mechanical - hydraulic interlocking protection.

The nlekota oru usoro tumadi Monitors na mmanụ okpomọkụ, ihe onwunwe okpomọkụ, usoro bufee, usoro na akụrụngwa ọdịda nke injection ịkpụzi igwe, na-egosi ma ọ bụ Mkpu ndiiche ọnọdụ.

Mestech kwadebere 30 setịpụrụ ịkpụzi igwe na-ekpuchi 100 tọn ruo tọn 1500, anyị nwere ike imepụta ngwaahịa plastik site na 0.50 gram na 5 n'arọ nke akụkụ plastik dị iche iche. Ọ bụrụ na ị nwere ngwaahịa plastik chọrọ ịkpụzi ọgwụ, biko kpọtụrụ anyị