Die mgbatị usoro

Nkọwa nkenke:

Die mgbatị usoro bụ usoro nke zinc, ọla kọpa, aluminom, magnesium, lead, tin na lead allo alloys na alloys ha na-agbaze na oke okpomọkụ ma na-agbanye n'ime oghere ebu, wee jụzie nrụgide iji nweta akụkụ.

The-arụ ọrụ okpomọkụ nke na-abụghị ferrous metal anwụ mgbatị bụ nnọọ ala karịa nke ígwè mgbatị, na kwekọrọ ekwekọ foundry ngwá na usoro chọrọ ndị dị mfe, na obere. Die mgbatị mmepụta nwere ike inweta ezigbo mma elu mma na akụkụ ziri ezi, ọkachasị nke ọma maka nrụpụta dị oke mkpa nke obere na ọkara akụkụ, nke na-enye ezigbo nkwado maka elektrọnik, ngwa eletriki, ụgbọala, ụgbọala, ngwaọrụ ahụike, ngwa na akwa ngwaọrụ. Dị iche iche metal alloys nwere ọtụtụ dị iche iche agwa na-anwụ mgbatị usoro. Ngalaba ha kachasị dị ntakịrị na nke kacha nta dị iche, agbaze agbaze ọkụ dị iche, ngbacha ihu dị iche, Ya mere, ọ kachasị mma itinye ndị otu injinia anyị n'oge n'oge usoro imepụta iji jiri ọrụ anyị nwere maka nrụpụta.

E nwere isi ihe ise na metal anwụ mgbatị usoro:

1.Die ihe nkedo;

2. ydị nke Ọnwụ Nkedo;

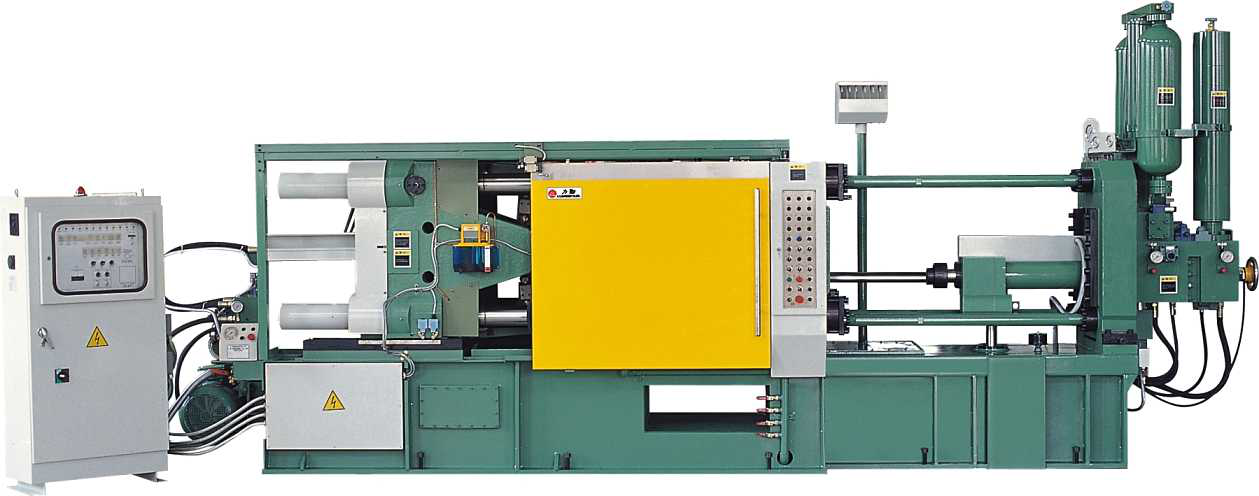

3.Die mgbatị igwe;

4.Die nkedo ebu;

5.Post nhazi na Finishing maka Die Nkedo Parts

Metal anwụ mgbatị usorobụ usoro ijikọ nrụgide, ọsọ na oge site na iji ihe atọ nke igwe, ebu na alloy. N'ihi na metal na-ekpo ọkụ na-arụ ọrụ, ịdị adị nke mgbali bụ isi e ji mara nke na-anwụ mgbatị usoro nke dị iche na ndị ọzọ mgbatị ụzọ. Nrụgide mgbatị bụ usoro nkedo pụrụ iche nke na-enweghị mkpụmkpụ, nke mepụtara ngwa ngwa na teknụzụ nhazi igwe ọgbara ọhụrụ. Ọ bụ usoro nke na-ejuputa ebu na metal a wụrụ awụ n'okpuru nnukwu nrụgide na nnukwu ọsọ, na -emepụta nkedo site na crystallization na solidification n'okpuru nrụgide dị elu. High mgbali na elu na-agba bụ isi e ji mara na-anwụ mgbatị. Nrụgide a na-ejikarị eme ihe bụ iri puku megapascals, njuputa ọsọ (ọsọ ọsọ dị n'ime) bụ ihe dịka 16-80m / s, na oge njuju nke mmiri mmiri na oghere dị mkpụmkpụ, ihe dịka 0.01-0.2s. Metal anwụ mgbatị bụ a metal mgbatị usoro na e ji ese wụrụ awụ metal n'okpuru elu nsogbu n'ime a ebu oghere. A na-eji oghere ígwè na isi eme ihe site na iji nchara anwụrụ anwụ anwụ nke arụgoro n'ime ya ma rụọ ọrụ yiri nke nkedo nkedo n'oge usoro ahụ. Dabere n'ụdị ígwè a na-atụba, a na-eji igwe na-ekpo ọkụ ma ọ bụ nke dị jụụ.

1.Die nkedo ihe onwunwe MESTECH na-enye ihe nkedo na-anwụ maka zinc alloy, alloy alloy na alloy magnesium. N'ihi na ndị a atọ ihe ndị kasị ọtụtụ ebe ada anwụ ningfe alloy ihe ugbu a.

Zinc alloy njirimara:

--- Ike na ike

--- Ezigbo arụmọrụ eletrik

--- Omume ọkụ dị elu

--- Akụrụngwa dị ọnụ ala

--- Nnukwu nhazi na nkwụsi ike

--- Ezigbo ike mgbidi

--- Ike oyi ụdị, nke eases iso

--- Ogologo mmecha njirimara

--- Ngosipụta nkwụsị nke corrosion --- recyclability zuru ezu

2.Aluminium Alloy Njirimara:

--- Igwe na-arụ ọrụ dị elu

--- Pụtara ìhè corrosion eguzogide

--- fechaa

--- Ezigbo ike na ike

--- Ezi nkwekọrịta na ike-na-arọ ruru

--- Magburu onwe EMI na RFI echebe Njirimara

--- Ezigbo nrụpụta ọkụ

--- Ọdụdọ eletriki dị elu

--- Ezigbo njirimara zuru ezu

--- Ntughari zuru ezu

3. Njirimara Magnesium Alloy:

--- Omume dị elu; eletrik, na nke kwesiri

--- Na-eguzogide oke okpomọkụ

--- Nnukwu nhazi na nkwụsi ike

--- Ike mgbidi dịpụrụ adịpụ pụrụ iche

--- Ezigbo nguzo gburugburu ebe obibi

--- Ezigbo njirimara zuru ezu

--- Ntughari zuru ezu

1 The Hot-Chamber Die Nkedo Usoro

Hot-ulo anwụ mgbatị, mgbe ụfọdụ a na-akpọ gooseneck mgbatị, bụ ihe na-ewu ewu nke abụọ anwụ mgbatị Filiks. Na usoro a, a na-emikpu ụlọ nke silinda nke usoro ntanye kpamkpam na bat ahụ a wụrụ awụ. Otu usoro nri gooseneck na-adọta ọla a wụrụ awụ n'ime oghere nwụrụ.

Ọ bụ ezie na nmikpu miri emi na bat ahụ a wụrụ awụ na-enye ohere maka ngwa ngwa ngwa ngwa ngwa ngwa, ọ na-emekwa ka ọnya dị nro. N'ihi nke a, na-ekpo ọkụ-ụlọ anwụ mgbatị usoro kacha mma ruru eru maka ngwa na-ahu nagide ọla na ala agbaze ihe na nnukwu fluidity. Ezi ọla maka ọkụ-ụlọ anwụ mgbatị usoro gụnyere ụzọ, magnesium, zinc na ọla kọpa.

2 Nzuzo-ụlọ anwụ Nkedo Usoro

The oyi-ụlọ anwụ mgbatị usoro yiri nnọọ na-ekpo ọkụ-ụlọ anwụ n diefe. Na a imewe na-elekwasị anya na mbenata igwe corrosion kama mmepụta arụmọrụ, gbazee metal na-akpaghị aka- ma ọ bụ aka-ladled n'ime ọgwụ usoro. Nke a na-ewepụ mkpa maka usoro ịgba ntụtụ ka emikpu ya n'ime batrị a wụrụ awụ.

Maka ngwa ndị na-emebi emebi maka imikpu mmiri nke ime ụlọ na-ekpo ọkụ na-anwụ, usoro ime ụlọ oyi nwere ike ịbụ ụzọ ọzọ dị mma. Ngwa ndị a gụnyere nkedo nke ọla nwere nnukwu agbaze agbaze, dị ka aluminom na aluminom alloys.

3 The Low-Pressure Die Nkedo Usoro

Obere nrụgide ịnwụ bụ usoro kacha mma maka akụrụngwa aluminom bụ nke dị gburugburu gburugburu. Dịka ọmụmaatụ, a na-echekarị wiil ụgbọ ala site na nkedo ịnwụ anwụ. N'ụdị usoro a, ebu ahụ dị n'elu igwe batrị a wụrụ awụ ma jikọọ ya site na tube riser. Mgbe a na-agbanye ụlọ ahụ (nke na-adịkarị n'etiti 20 na 100kPa), a na-adọta ígwè ahụ elu ma banye na ebu ahụ. Mkpochapu feeders site na nke a ụdị anwụ mgbatị usoro anapụta elu mgbatị zaa.

4 Agụụ Die Nkedo Usoro

Agụụ mgbatị mgbatị (VPC) bụ a dịtụ ọhụrụ anwụ mgbatị usoro na-anapụta enwekwukwa ike na di ntakiri porosity. Usoro a dị ka obere mgbatị ịnwụ mgbatị, belụsọ ọnọdụ nke nkedo nkedo na nchara mmiri a wụrụ awụ na-atụgharị. Chamberlọ cylinder ahụ nwere ike ịghọ ihe agụụ, nke na-amanye ọla a wụrụ awụ n'ime oghere ebu. Nhazi a na-ebelata ọgba aghara ma na-egbochi oke gas inclusions. Agụụ anwụ mgbatị bụ karịsịa bara uru na ngwa kara aka maka post-ningfe okpomọkụ ọgwụgwọ.

5 The Afanyekwa Die Nkedo Usoro

Ejiri nkedo mpịakọta dị ka ihe ngwọta dị irè maka nkedo ọla na alloys nwere obere mmiri. N'ime usoro a, ọla a wụrụ awụ na-ejupụta ihe na-emeghe, nke na-emechi emechi, na-amanye metal ahụ n'akụkụ akụkụ nke ịkpụzi. Afanyekwa na mgbatị usoro anapụta oké ok ngwaahịa na bụ a arụkọ usoro ụdi okpomọkụ-n'imeso. A na-ejikọkarị usoro a na aluminom a wụrụ awụ, a na-ejikwa ya na ngwa ndị na-akpọ maka mgbatị fiber.

6 Usoro Njikere Nke Ọnwụ

Ọkara siri ike ịnwụ, mgbe ụfọdụ a na-akpọ Thixoforming, bụ usoro ọzọ na-anapụta obere porosity na oke njupụta. A igwe egbutu workpiece n'ime obere slugs, na mgbe ahụ kpụ ọkụ n'ọnụ. Ozugbo ọla ahụ eruola mgbanwe nke oge n'etiti ihe siri ike na mmiri mmiri, na-ebute ihe dị ntakịrị slushy, aka uwe na-amanye ya n'ime oghere ahụ, ebe ọ na-esi ike. Uru nke a ka mma nkenke. A naghị ejikarị ọla kọpa dị ka magnesium alloy na alloy alloy na usoro nkedo ọkara siri ike.

Tdị ofdị Nwụrụ Anwụ

All anwụ mgbatị usoro iche iche e mere na otu ihe mgbaru ọsọ n'uche-kpụa akpụru bẹ ọ dụ l'ẹka. Dabere na ụdị gbazee metal, akụkụ jiometrị na akụkụ size, dị iche iche anwụ mgbatị Filiks nwere ike ịnapụta elu pụta n'elu ọzọ ụzọ. The abụọ bụ isi ụdị nke na-anwụ mgbatị Filiks na-ekpo ọkụ-ụlọ na oyi na-atụ-ụlọ anwụ ningfe. Ọdịiche dị iche iche n'ụdị ọnwụ abụọ a gụnyere:

Low-mgbali die nkedo

Agụụ anwụ mgbatị

Afanyekwa anwụ mgbatị

Ọkara siri ike ịnwụ

1 Hot mgbali ulo anwụ mgbatị igwe

Dika nhazi na nhazi nke ulo, enwere ike kewaa ya na uzo di iche. A na-etinye ihe nkedo maka ígwè a wụrụ awụ na igwe ahụ site na ụlọ ọkụ na-ekpo ọkụ ọkụ, a na-etinyekwa ihe piston maka nrụgide hydraulic metal na-abanye na ebu. Hotfọdụ na-ekpo ọkụ ịpị ụlọ anwụ casters iji abịakọrọ ikuku ozugbo ịgbanye metal haịdrọlik nsogbu n'ime ebu enweghị pistin usoro.

Hot ulo anwụ ningfe igwe

The na-ekpo ọkụ ịpị ulo anwụ mgbatị igwe na-bụ-eji maka anwụ-n allofe alloy na ala agbaze ebe, dị ka zinc, Magnesium na tin.

2 Oyi mgbali ulo anwụ n castfe igwe

Agbaze metal n'èzí igwe na mgbe ahụ na-agbakwunye mmiri mmiri metal n'ime mkpakọ ụlọ na ngaji nwere ike kere n'ime vetikal oyi ụlọ anwụ ningfe igwe na kehoraizin oyi ụlọ anwụ ningfe igwe dị ka ntụziaka nke ngagharị nke mkpakọ pistin.

Liquid metal wepụrụ ọkụ nke vetikal oyi pịa ụlọ anwụ ningfe igwe na wụsara n'ime mkpakọ ụlọ. The metal bụ haịdrọlik-enwe n'ime ebu site mkpakọ pistin, na njupụta metal na-kewapụrụ site ọzọ pistin.

Oyi ụlọ anwụ ningfe igwe

Oyi ụlọ anwụ ningfe igwe

Kehoraizin oyi ụlọ anwụ ningfe igwe bụ otu ihe ahụ dị ka vetikal otu, ma pistin ije bụ kwụ. Kacha oge a na-anwụ mgbatị igwe bụ kwụ. Nzuzo-ulo anwụ-mgbatị igwe nwere ike ịnwụ-nkedo elu agbaze mgbe ọla ma ọ bụ mfe oxidized ọla, dị ka aluminom, ọla kọpa alloys, wdg

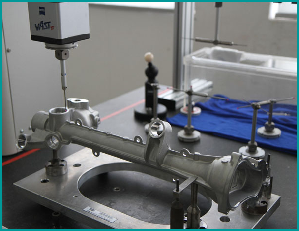

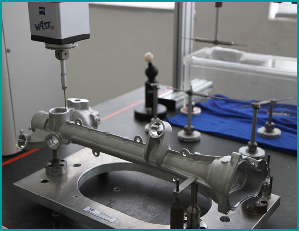

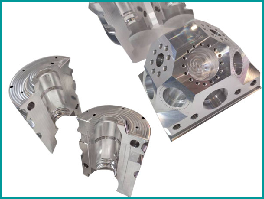

3.Die mgbatị igwe.

Die mgbatị igwe na-eji maka mgbatị mgbatị igwe. Ọ na-agụnye iche iche nke na-ekpo ọkụ ịpị ulo anwụ n castfe igwe na oyi na-atụ ịpị ulo anwụ n castfe igwe. The oyi ịpị ulo anwụ ningfe igwe na-ekewa abụọ na ụdị: ogologo na kehoraizin. The wụrụ awụ metal na-agbara na ebu site na-anwụ-mgbatị igwe n'okpuru ihe nke mgbali nke jụrụ na-akpụ, na ndị siri ike metal oge ọgbụgba nwere ike nweta mgbe ebu meghere.

Hot ulo anwụ ningfe igwe

Oyi ụlọ anwụ ningfe igwe

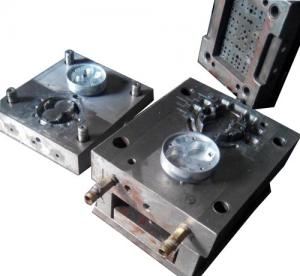

4.Die nkedo ebu

N'ihe dị iche iche dị iche iche, ọnọdụ ọrụ nke ịnwụ anwụ na-anwụ dị njọ. Die mgbatị bụ ime ka a wụrụ awụ metal jupụtara ebu oghere n'okpuru elu nsogbu na elu na-agba, na kọntaktị na-ekpo ọkụ metal ugboro ugboro n'oge na-arụ ọrụ usoro. Ya mere, anwụ ningfe ebu chọrọ ka nwere elu kwes ike ọgwụgwụ na-eguzogide, kwes conductivity na-eyi ndị na-eguzogide, corrosion-eguzogide, mmetụta ekweghị ekwe, red ekweghị ekwe, ezi demoulding na na. Ya mere, n'elu ọgwụgwọ technology nke na-anwụ ningfe anwụ na-achọ elu technology.

Die mgbatị ebu

5.Post nhazi na Finishing maka Die Nkedo Parts

Anyị na-enye ọtụtụ nhazi ọrụ na ịmecha ọrụ maka akụkụ ndị nwụrụ anwụ sitere na ndị mmekọ anyị ahọpụtara:

Ọrụ

CNC machining - vetikal, kehoraizin, mbịne, 5-axis

Ihe mkpuchi ntụ ntụ

Mmiri Liquid

EMI - Ọta RFI

Mbanye - chrome, ọla kọpa, zinc, nickel, tin, gold

Anodizing, Eletriki mkpuchi, Chromating / Non-chromating

Ọgwụgwọ Heat, Passivation, Tumbling

Ihe eserese

Ime ụlọ Artwork Usoro

Nyocha Silk

Kedo akwa Obibi

Bead ọgbụgba ọkụ

Light Mechanical Assembly, gụnyere stud na helikọl ntinye, O-mgbanaka, gasket

Laser tingcha na osise

Etching

Igwe mkpuchi eletrik & Silk